Iso 14644 1 class 7 is a set of standards for determining and classifying the cleanliness of air in environments. This standard defines particle size monitoring limits to maintain cleanroom air quality, with classes ranging from ISO 9 to ISO 8. It is important for manufacturers and laboratories working in these highly controlled environments to observe these standards to ensure their products meet industry requirements.

Table Of Content:

- ISO 14644-1 Class 7 Cleanroom Classification Guidelines

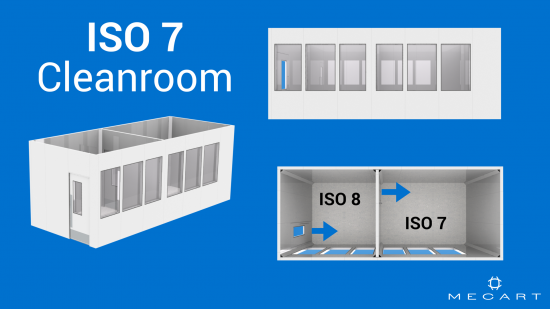

- Clean Room Classifications (ISO 8, ISO 7, ISO 6, ISO 5) | Mecart

- ISO 14644-1:2015 - Cleanrooms and associated controlled ... - ISO

- ISO 7 Clean Room Manufacturer | Class 10000 Clean Rooms

- INTERNATIONAL STANDARD ISO 14644-1

- Clean Room Classifications & ISO Standards | Quotes - 48 Hours

- Understanding Cleanroom Classifications (ISO 8, ISO 7, ISO 6, ISO 5)

- The beneficial effect of air cleanliness with ISO 14644-1 class 7 for ...

- Cleanroom - Wikipedia

- Watson-Marlow to open ISO 14644-1 Class 7 cleanroom

1. ISO 14644-1 Class 7 Cleanroom Classification Guidelines

https://www.connect2cleanrooms.com/knowledge-base/iso-14644-1-class-7-cleanroom-classification-guidelines?___store=EN&___from_store=EN

2. Clean Room Classifications (ISO 8, ISO 7, ISO 6, ISO 5) | Mecart

https://www.mecart-cleanrooms.com/learning-center/cleanroom-classifications-iso-8-iso-7-iso-6-iso-5/

3. ISO 14644-1:2015 - Cleanrooms and associated controlled ... - ISO

https://www.iso.org/standard/53394.html

4. ISO 7 Clean Room Manufacturer | Class 10000 Clean Rooms

https://www.cleanroomsbyunited.com/modular-cleanrooms/class-10000-cleanrooms

5. INTERNATIONAL STANDARD ISO 14644-1

https://zoser.com.co/wp-content/uploads/2015/10/ISO%2014644-1%20Version%202015.pdf

This part of ISO 14644 specifies classes of air cleanliness in terms of the ... ISO 14644-7, Cleanrooms and associated controlled environments — Part 7: ...

6. Clean Room Classifications & ISO Standards | Quotes - 48 Hours

https://www.americancleanrooms.com/cleanroom-classifications/

ISO 14644-1 Cleanroom Standards | Cleanroom Classifications ... Hybrid works best for less demanding ISO-7 or ISO-8 class cleanrooms. Softwall Cleanroom ...

7. Understanding Cleanroom Classifications (ISO 8, ISO 7, ISO 6, ISO 5)

https://www.linkedin.com/pulse/understanding-cleanroom-classifications-iso-8-7-6-5-charles-lipeles

8. The beneficial effect of air cleanliness with ISO 14644-1 class 7 for ...

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6133589/

Sep 7, 2018 ... The beneficial effect of air cleanliness with ISO 14644-1 class 7 for surgical intervention in a neonatal intensive care unit · 1. Introduction.

9. Cleanroom - Wikipedia

https://en.wikipedia.org/wiki/Cleanroom

10. Watson-Marlow to open ISO 14644-1 Class 7 cleanroom

https://www.cleanroomtechnology.com/news/article_page/Watson-Marlow_to_open_ISO_14644-1_Class_7_cleanroom/189381

What is Iso 14644 1 class 7?

Iso 14644 1 class 7 is a set of standards used by laboratories and manufacturers in high-control settings. This standard defines particle size monitoring limits to maintain cleanroom air quality, with classes ranging from ISO 9 to ISO 8.

What are the particle size monitoring limits?

The particle size monitoring limits depend on the requirements of the application being performed but are generally 0.06 micron or greater in diameter. These limits must be adhered to ensure that product specifications are met.

Why is it important that Iso 14644 1 class 7 standards are followed?

It is important that laboratories and manufacturers adhere to Iso 14644 1 class 7 standards because failing to do so can result in unsatisfactory product performance due to too much dust or other particles getting into the environment. Following these standards ensures that your products will meet industry requirements when released into the market.

How often should laboratory personnel check their environment's air quality?

Laboratory personnel should check the atmosphere at least once per shift, as well as any time there is a change in personnel or product within their environment. Additionally, if tools or equipment enters an environment then it should be checked for proper purity prior to beginning work with it.

Are there penalties for not following Iso 14644 1 class 7 standards?

Yes, companies that fail to comply with Iso 14644 1 class 7 can face fines from government regulatory agencies such as OSHA depending on their violation(s). In certain cases, businesses may also be liable for damages caused by faulty products due to insufficient environmental control measures not being implemented according to this standard's requirements.

Conclusion:

Adhering strictly and properly implementing Iso 14644 1 Class 7 is vital for any laboratory or manufacturing setting where high purity levels must be maintained. Having an understanding of this standard's particle size monitoring limits as well as its importance will help companies avoid costly regulatory violations while ensuring they produce safe and reliable products every time they ship out goods.